china slurry sand pump factories

Latest articles

Working principle

china slurry sand pump factories...

china slurry sand pump factories 【china slurry sand pump factories】

Read MoreSlurry Pump

china slurry sand pump factories...

china slurry sand pump factories 【china slurry sand pump factories】

Read MoreOne of the most frequently asked questions from our team of pump experts is: How do I pump slurry? With this in mind, our team of experts have provided a useful guide to pumping slurry.

china slurry sand pump factories...

china slurry sand pump factories 【china slurry sand pump factories】

Read More>Slurry Pump

china slurry sand pump factories...

china slurry sand pump factories 【china slurry sand pump factories】

Read MoreChoosing the right target=_blank title=Slurry Pump>slurry pump for your application can be a daunting task. Slurry pumps can be found in almost all industries and play a vital role in many processes.The 4 key aspects to look for when determining the right slurry pump are slurry pump design, pump materials of construction, slurry pump seals, and proper slurry pump power sizing.Next, the target=_blank title=Slurry Pump Supplier>slurry pump supplier will share them with you.

china slurry sand pump factories...

china slurry sand pump factories 【china slurry sand pump factories】

Read MoreDetermine the operating parameters of the pump.

china slurry sand pump factories...

china slurry sand pump factories 【china slurry sand pump factories】

Read More- Reduced space requirements - Since submersible slurry pumps operate directly in the slurry, they do not require any additional support structures.

china slurry sand pump factories...

china slurry sand pump factories 【china slurry sand pump factories】

Read MoreSlurry Pump

china slurry sand pump factories...

china slurry sand pump factories 【china slurry sand pump factories】

Read MoreIf you have experience pumping slurry, you know it is not an easy task. Slurries are heavy and difficult to pump. They can cause excessive wear on the pump and its components, and if they don't move fast enough, they can clog the suction and discharge lines. Most importantly, it can be a challenge to keep a slurry pump in use for a reasonable period of time. However, there are steps you can take to extend the life of your slurry pump and reduce the challenges of pumping slurry.

china slurry sand pump factories...

china slurry sand pump factories 【china slurry sand pump factories】

Read MoreIn a subsea installation, the slurry pump runs directly in the slurry and does not require a support structure, which means it is flexible and easy to install. If possible, the catch basin should be equipped with sloping walls to allow sediment to slide down into the area directly below the pump inlet. Agitators should be used when the liquid contains large amounts of solids and has a high particle density. Freestanding or side-mounted (submersible) mixers are an excellent choice for resuspended solids, especially if the catch basin is large or does not have sloping walls.

china slurry sand pump factories...

china slurry sand pump factories 【china slurry sand pump factories】

Read More

Popular articles

- Firstly, analysing your duty helps us to determine whether you are using the type and size of pump best suited to your needs. Cavitation can occur due to surges; a very effective way to solve this problem is to install a choke on the pump head to increase the pressure on the casing, which then absorbs the surge, or to add a choke to the output to reduce the surge.

- The dredge pump is designed to draw sediment, debris and other hazardous materials from the surface layer into the suction pipe and transport the material through the pipe to the discharge site. The pump must be able to handle common solid debris of various sizes that can pass through the pump, thus minimizing the downtime required for cleaning.

- The dredge pump is designed to draw sediment, debris and other hazardous materials from the surface layer into the suction pipe and transport the material through the pipe to the discharge site. The pump must be able to handle common solid debris of various sizes that can pass through the pump, thus minimizing the downtime required for cleaning.

- What style of pump is suitable?

- Rubber is lighter and softer than other wear lining materials. This aids installation because it is easier to lift and install quickly and efficiently. Positive results for the health and safety of workers in the field.

- - Lower operating costs - Typically, submersible slurry pumps require much lower operating costs than dry mounted pumps due to higher efficiency.

Latest articles

-

Firstly, analysing your duty helps us to determine whether you are using the type and size of pump best suited to your needs. Cavitation can occur due to surges; a very effective way to solve this problem is to install a choke on the pump head to increase the pressure on the casing, which then absorbs the surge, or to add a choke to the output to reduce the surge.

-

The slurry weight or consistency determines the type, design and capacity of the slurry pump required. If you have any questions about the best pump for your application, welcome to >contact us today or request a quote.

-

With the standard flush schedule, the flow is usually adjusted by compressing the packings until a few drops of water are observed leaking from the seals on the drive side. In a quench schedule the flow rate is set by adjusting the inlet valve, while a valve is used on the exhaust side to maintain the correct seal tank pressure. If the outlet water from the seal box is too hot, the flow rate is increased until the outlet water cools, while still maintaining the correct seal box pressure.

-

of a thick consistency, and.

-

High head (i.e. the height to which the pump can move the liquid)

-

WZ series slurry pumps are developed on the wide adaption of both home and abroad advance technology and many years of slurry pump design and field operation experiences.

Links

Воситаи таъсирбахшии ин усул ин аст, ки бесаруватиҳои коркард аз маблағгузорӣ бештари гармадаро талаб мекунад. Барои ҳамин, ин усул барои сохтмон ва истеҳсоли маҳсулот боздикист бо хосиятҳои намоён ва манфиатҳои иқтисодӣ, вақте истифода мешаванд.

The manufacturing process of spring steel coils involves careful control of chemical composition and heat treatment. Heat treatment processes such as hardening and tempering enhance their mechanical properties, allowing manufacturers to tailor the coils' characteristics to meet specific performance requirements. These processes not only improve the strength-to-weight ratio but also increase the operational lifespan of the springs made from these coils.

Green Mesh Fencing Panels The Perfect Blend of Functionality and Aesthetics

Sammanfattningsvis är väggförbindningar avgörande för att säkerställa hållbarheten och stabiliteten hos stenmurverk. Genom att noggrant välja rätt typ av förbindning och korrekt installera dem, kan byggare och arkitekter skapa strukturer som inte bara är funktionella utan också vackra. I dagens bygge är det viktigare än någonsin att bevara traditionella tekniker samtidigt som man införlivar moderna metoder för att skapa långvariga och effektiva lösningar.

4. Industrial Machinery Industrial applications utilize compression springs in conjunction with other mechanisms to create stable platforms, maintain tension in conveyor systems, and in various mechanical linkages.

Tips for Choosing Chicken Wire Fencing

When budgeting for a chain link fence, consider not just the materials and installation, but also potential landscaping adjustments or additional features. A well-planned budget should account for all aspects of the project to avoid unexpected costs.

- .

- - Concrete Mix The compatibility of the wire mesh with the concrete mix design is crucial. Ensure that the concrete used has sufficient workability to encompass the mesh without leaving gaps.

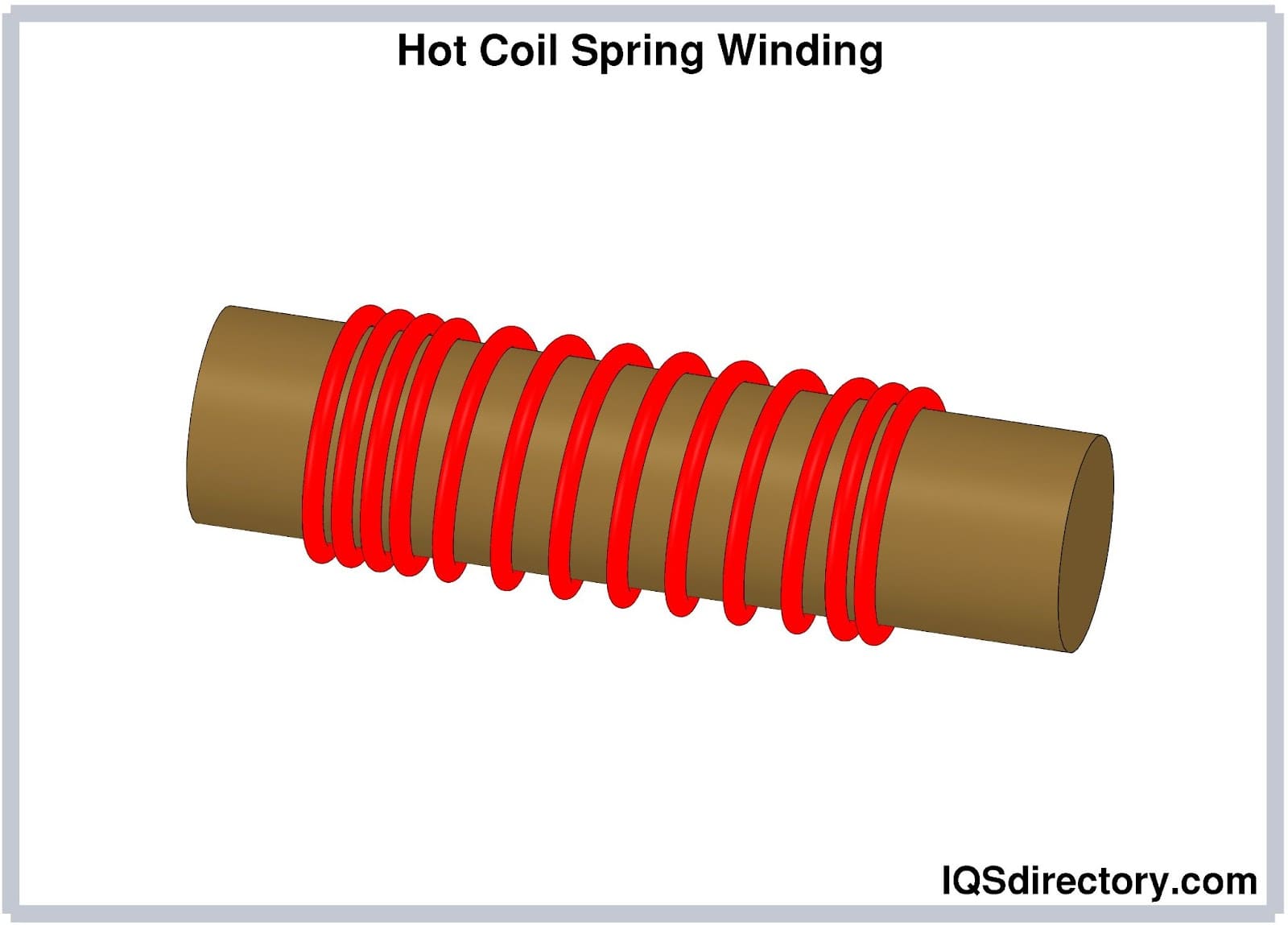

The choice of material and manufacturing process for coil springs varies depending on the production scale. Small production runs are typically completed using a lathe, while high-volume production is done with automated coiling machines or computer numerical control (CNC) equipment.

Advantages of Spiral Wound Torsion Springs

11 gauge galvanized wire, ya'ni 11 qavat qoplangan temir sim, zamanımızda köpp yerdin istifadė qilinmaqta

. Bu sim türü, özining kütikligi we aşınmağa qarşı tura bilish xususiyiti sebäpli, köplab qurulush we işlab chiqiriş sohalarida muhim rol o'ynaydu.A machined spring with residual stress in the free state will be subject to freestate deformation, which is always undesirable. Materials subjected to solution annealing resist residual stress, as do materials that undergo heat treatment with no cold reduction or quenching. Quenching will, by itself, induce residual stress. Therefore, good choices are martensitic corrosion resistant steels (CRES) and martensitic steels.

- - Concrete Mix The compatibility of the wire mesh with the concrete mix design is crucial. Ensure that the concrete used has sufficient workability to encompass the mesh without leaving gaps.

Compression springs are also essential in construction and agricultural equipment, where they provide the necessary force to operate tools and machinery effectively. In recreational equipment like trampolines and exercise machines, compression springs provide the necessary resistance and energy return to enhance performance and safety.

- Environmental Conditions The type of environment where the concrete structure will be placed should dictate the choice of wire mesh. In corrosive environments, protective coatings may be necessary to prevent rust and degradation.

Konteyner bağçılığında pomidor kafeslərinin istifadəsi, bitkilərin böyümə müddətində onları daha yaxşı idarə etməyə imkan verir. Bitkiləri yüksəldərək, onların tərpənməsini dərhal izləyə bilir və zərərvericilərdən daha asan qoruya bilirsiniz. Özünüzü problemli zonasını təsbit etdiyiniz zaman, bitkiləri daha effektiv bir şəkildə müalicə edə bilərsiniz.

The basic principle of these springs is simple, but the materials and manufacturing processes involved can be quite complex. Wire springs are typically made from high-carbon steel, stainless steel, or specialized alloys, allowing manufacturers to tailor the mechanical properties of the springs according to the requirements of the application.

In conclusion, white grid wall panels represent a sophisticated and versatile solution for interior design challenges. Their ability to merge beauty with functionality makes them a favorite among homeowners, interior designers, and business owners alike. By choosing these panels, you not only enhance the visual appeal of your space but also introduce a practical storage and display solution that can adapt to changing needs. As the trend towards minimalism continues to grow, incorporating white grid wall panels into your design repertoire could be the key to achieving a modern, stylish, and functional environment.

Die Prävention ist der Schlüssel zur Vermeidung von Wandankerfehlern. Regelmäßige Inspektionen und Wartungen, fachgerechte Installation und die Wahl von hochwertigen Materialien sind entscheidend. Darüber hinaus sollten Bauherren und Architekten sich über die neuesten Technologien und Materialien informieren, um die Langlebigkeit und Sicherheit ihrer Konstruktionen zu gewährleisten.

During spring, many feel a surge of inspiration and motivation. The longer days and warmer temperatures encourage outdoor activities, whether it’s hiking, gardening, or simply taking a stroll in the park. This renewed energy is a reminder of the importance of movement and action in our lives. Just as nature is in constant motion—flowers blooming, trees budding, and animals awakening—we too must embrace the momentum that comes with change.

V závěru lze říci, že zakázkové točivé pružiny představují klíčový prvek v moderní výrobě a technologii. Poskytují flexibilitu, přesnost a spolehlivost, což z nich činí nezbytnou součást mnoha produktů a zařízení. S neustálým rozvojem technologií a materiálů se očekává, že poptávka po těchto přizpůsobených komponentách bude i nadále růst.

أهمية روابط الجدران الصلبة

Advantages of Big Compression Springs

Slot widths vary between wire and machined springs, even though these components have the same length, OD, and compression rate.

In the world of livestock management, the versatility and practicality of cattle panels cannot be overstated. Cattle panels, or livestock panels, are essential structures made typically from heavy-duty steel that are designed to contain and manage cattle efficiently. These panels serve a variety of purposes, making them invaluable for farmers and ranchers alike.

Maintenance and Care of Compression Coil Springs

Compression Springs

Pagbaba ng Coil Springs Isang Mahalagang Aspeto ng Pagpapahusay ng Sasakyan

When constructing your own supports, consider the following

Examples of applications for coil springs include:

The Benefits of Metal A-Frame Sign Holders

Light Duty Extension Springs An Overview

販売店では、様々な種類のコイルスプリングが取り扱われています。標準的なスプリングから、カスタム設計のスプリングまで、ニーズに応じた選択肢が用意されています。特に、車両改造や特別な用途に対応したスプリングは、多くのユーザーから人気を集めています。顧客は、自分の車や機械の仕様に合った最適なスプリングを見つけることができるのです。

coil springs for sale

In conclusion, spring steel coils play a vital role in numerous applications due to their remarkable combination of strength, elasticity, and durability. Understanding their properties and the processes behind their production allows industries to leverage these materials effectively, leading to innovative designs and efficient solutions in various engineering challenges. As technology advances, the demand for high-performance materials like spring steel coils will only continue to grow, driving further research and development in this field.

- Elige el Tamaño Adecuado Asegúrate de seleccionar estacas que sean del tamaño adecuado para tus carteles. Generalmente, unas estacas de aproximadamente 30 a 40 pulgadas funcionan bien para la mayoría de los carteles de yardas.